HOME

> Handling the GummyWax

HOME

> Handling the GummyWax

|

|

The production process for candles using the GummyWax requires no special facilities and the candles

can be produced

with the same tools and materials as for normal translucent gel waxes.

Here we will explain the points to keep in mind such as for temperature control for melting the wax.

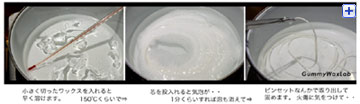

How to Melt the GummyWax

As with normal translucent wax, please use a hot plate or induction cooker as there is a danger of mist

As with normal translucent wax, please use a hot plate or induction cooker as there is a danger of mist

or ignition with an open flame such as with a gas burner.

or ignition with an open flame such as with a gas burner.

|

Please start by keeping the temperature settings low for the hotplate

Please start by keeping the temperature settings low for the hotplate

or induction cooker and slowly melting the wax.

Always measure the temperature so that different parts do not become too

hot and begin to slowly dissolve the wax while stirring it.

When you have melted around half of the wax, completely melt the wax into a

When you have melted around half of the wax, completely melt the wax into a

liquid while adjustingthe temperature of the induction cooker.

If you heat the wax at a high temperature right away the wax will vaporize

If you heat the wax at a high temperature right away the wax will vaporize

and cause a mist.

If you raise the temperature to 180°C or more there may be some discoloration

as a result of heat oxidation.

This is a highly elastic free standing wax that maintains its form and its pour

This is a highly elastic free standing wax that maintains its form and its pour

point is high, at around100°C- 110°C, so cut the wax into somewhat thin pieces

and then melt for more efficient melting.

Please use a thermometer that allows you to measure up to 200°C.

Please use a thermometer that allows you to measure up to 200°C.

Please do not re-melt the wax for reuse more than twice.

Please do not re-melt the wax for reuse more than twice.

If you use the wax too many times the wax may deteriorate due to oxidation,

as with other waxes.

The optimal temperature for use for the GummyWax is between roughly

The optimal temperature for use for the GummyWax is between roughly

140° and 160°C.

If you leave the wax for several minutes at around 160°C

If you leave the wax for several minutes at around 160°C

you can cause some bubbling.

The appearance of the air bubbles differs depending on the pouring

The appearance of the air bubbles differs depending on the pouring

temperature and technique, and the mold surface finishing.

Attention!

Attention!

Please always avoid mixing this wax with the translucent waxes

of other companies.

There is a danger that the wax may ignite when the candle is lit.

Please always use the GummyWax by itself.

|

|

|

|

We are sometimes asked whether you can use normal wicks for the GummyWax,

but the GummyWax does not require

a special wick.

Wicks used for normal candles are fine.

No special wick is required

No special wick is required

|

You may use commercially available versatile wicks that are made in Japan

You may use commercially available versatile wicks that are made in Japan

or abroad.

As shown in the pictures to the right, there are both round plaited wicks,

or round wicks, and flat plaited wicks, or flat wicks.

Round wicks may be used for waxes with a high combustion temperature such as

with beeswax, but it is probably okay to use them with the GummyWax such as

for floating candles that do not use metal stands as these wicks are sturdy

and the wick will not fall over even if the pool of melted wax becomes large.

Flat wicks are normally used, but in this case one has to add a metal stand

and arrange it somehow so that it is difficult for the wick to fall over

in the poolof melted wax.

Some people use a metal stand around 10 mm in size for the part where

the wick is inserted, but as this inorganic metal part stands out it's

also necessary to design the candle to hide this such as by drawing

attention to the air bubbles and other things.

Because the melting point for the GummyWax is high it is difficult

Because the melting point for the GummyWax is high it is difficult

for a large pool of melted wax to form and this means that the wax

does not deform easily.

There are a variety of ways to select a wick depending on the candle

design, but the best choice for a wick that will continue to burn

in a pool of melted wax is one about 25 mm in diameter.

Wick Coatings

Wick Coatings

We recommend dipping and coating the wick in the GummyWax before

We recommend dipping and coating the wick in the GummyWax before

use as with how one prepares normal wicks.

This is because one has to soak the wick in wax beforehand as

it will require some time before the flame reaches a stable size

when you first light the candle.

|

|

|

|

In the Tohoku and Hokkaido dialects "bokko" refers to a stick of wood.

We are presenting one bokko to the individuals who places orders for the first time.

We are presenting one bokko to the individuals who places orders for the first time.

|

We were worried about inserting wicks into finished candles.

Even if it’s fine to be able to set the wick in the mold, there is no tool for inserting

a wick into a candle where the wick has to be inserted afterwards.

After all this worrying we decided to make something by hand.

We dried wood from the hill behind the workshop over a summer and used aluminum poles

that we sharpened and added an edge to.

The wicks went in surprisingly easily and production efficiency increased.

Following this we made further improvements for easier use and we are offering these

as presents hidden among the wax to those individuals ordering the GummyWax for the

first time.

It seems that there are also individuals who need multiple bokko such as for workshops.

It seems that there are also individuals who need multiple bokko such as for workshops.

As wood is a natural product the quality is uneven and so we are not selling bokko but

we will respond to requests.

|

|

|

|

You can use dyes and pigments for normal candles and liquid dyes for translucent wax to

You can use dyes and pigments for normal candles and liquid dyes for translucent wax to

color the GummyWax.

|

Dyes are susceptible to ultraviolet rays which can cause their color to fade,

Dyes are susceptible to ultraviolet rays which can cause their color to fade,

but dyes will highlight the feel and the translucent quality of the wax.

There is no fear of the wick clogging and you can create candles with deep, rich colors.

Pigments do not fade or lose color easily, but if you add too much the wick will clog.

Pigments do not fade or lose color easily, but if you add too much the wick will clog.

You can color the wax with a small amount, but you should avoid adding too much.

Since the pigments are small granules or flakes it is difficult to get your hands dirty

and they're convenient to use.

Liquid dyes are also easy to dissolve into the gummywax.

Liquid dyes are also easy to dissolve into the gummywax.

You can color the wax with a small amount and the coloring is good quality.

It is also convenient to use a pipette to manage the drop volume.

Since these are concentrated dyes the trick is to add just a little bit at a time.

Add the coloring agent once the wax has become liquid and use after sufficient stirring.

Add the coloring agent once the wax has become liquid and use after sufficient stirring.

|

|

|

|

As with normal gel type translucent waxes,the wax can become clouded, normal combustion can be

As with normal gel type translucent waxes,the wax can become clouded, normal combustion can be

inhibited, and there can be a danger of ignition

as a result of the type of scent or the quality or blend of the scent.

It is the user’s responsibility to perform sufficient testing beforehand.

|

You can use fragrances for candles, synthetic fragrances (fragrance oils),

You can use fragrances for candles, synthetic fragrances (fragrance oils),

and essential oils.

Depending on the type of fragrance the fragrance may cloud the wax or be

Depending on the type of fragrance the fragrance may cloud the wax or be

unsuited for combustion.

Please use around 2 to 5% of the weight of the wax as a rough guide for

Please use around 2 to 5% of the weight of the wax as a rough guide for

how much of the scent component you should add.

Caution is needed as some types of fragrances significantly change the color with the

passing of time or themselves have color .

Caution is needed as some types of fragrances significantly change the color with the

passing of time or themselves have color .

In order to restrict the volatility of the scent as much as possible,

In order to restrict the volatility of the scent as much as possible,

cool the wax somewhat once you have melted it into a liquid, add the scent,

and slowly raise the wax to the desired temperature while stirring.

As fragrances are oils with low flash points please use after stirring well

As fragrances are oils with low flash points please use after stirring well

in order to prevent ignition.

Small bubbles will form depending on the type of scent, but if you leave it

for several minutes at around 150°C the bubbles will gradually disappear.

Small bubbles will form depending on the type of scent, but if you leave it

for several minutes at around 150°C the bubbles will gradually disappear.

Incompletely mixed scents may cause the flame to burn irregularly or

Incompletely mixed scents may cause the flame to burn irregularly or

may cause ignition.

Stir well so as to prevent pockets of the scent component.

|

|

|

Attention

Attention |

There is a danger of ignition when the GummyWax is mixed with the translucent waxes of other companies.

There is a danger of ignition when the GummyWax is mixed with the translucent waxes of other companies.

Please avoid mixing this wax with the translucent waxes of other companies. Please avoid mixing this wax with the translucent waxes of other companies.

Please use the GummyWax by itself. Please use the GummyWax by itself.

Please make sure that there are no air bubbles around the surface of the mold close to the wick

Please make sure that there are no air bubbles around the surface of the mold close to the wick

(around the area where the pool of melted wax forms). (around the area where the pool of melted wax forms).

As the surface touching the mold contains a significant amount of air there are cases where oxidation As the surface touching the mold contains a significant amount of air there are cases where oxidation

from air bubbles leads to irregular combustion. from air bubbles leads to irregular combustion.

Please do not re-melt the wax for reuse more than twice.

Please do not re-melt the wax for reuse more than twice.

The hardness and viscosity of the wax may change depending on the degree of oxidation and oxidation may

The hardness and viscosity of the wax may change depending on the degree of oxidation and oxidation may

also affect how the candle burns. also affect how the candle burns.

As with other waxes, users should perform stringent burn tests when using other additives such as scents

As with other waxes, users should perform stringent burn tests when using other additives such as scents

and coloring agents. and coloring agents.

|

|